At ViNS BIO, quality isn’t just a practice; it’s ingrained in our culture. For nearly twenty-five years, our unwavering dedication to quality has been the cornerstone of our mission to enhance lives. From every corner of our organization, our team is committed to producing and delivering products that meet the highest quality standards, adhering strictly to cGMP regulations across all operational aspects.

Our quality ethos, encapsulated in our policy “Commitment to Care for Life,” reflects our profound conviction that quality goes beyond meeting specifications—it’s a fundamental aspect of how we operate, defining every action taken by individuals and the company as a whole at ViNS BIO.

QUALITY ASSURANCE

- Quality Management System & Documentation (DMS)

- Qualification & Validation Section

- In-process Quality Assurance (IPQA)

- Analytical Quality Assurance

- Training & Compliance

QUALITY CONTROL

The Quality Control system is seamlessly integrated into every stage of the manufacturing process. Our Laboratory is equipped with sophisticated instruments and& approved technical employees that ensure a highly efficient quality control process. The QC lab includes:

- Instrumentation laboratory

- Packaging material testing laboratory

- Biological testing laboratory

- Microbiological testing laboratory

- Documentation section

- Stability chambers, Incubators and Control sample storage area

- Stability study and Method validation Section

- Small Animal Lab

QUALITY MANAGEMENT SYSTEM

At VINSBIO, quality is more than a mere action; it’s ingrained as a habit. For nearly three decades, our unwavering dedication to quality has been the cornerstone of our mission to give life its fullest expression. Across all facets and sites, our team is dedicated to crafting and delivering products that adhere to the most rigorous quality benchmarks, in alignment with cGMP regulations governing every operational aspect.

Our quality policy, “commitment to care for life,” reflects our profound conviction that quality transcends mere adherence to specifications; it embodies a fundamental ethos for every individual and entity associated with VINSBIO’s offerings.

QUALITY ASSURANCE

The Quality Assurance team owns our QMS. This team ensures quality is built every operation carried out at VINSBIO manufacturing facilities through

- Quality Management System & Documentation

- In-process Quality Assurance (IPQA)

- Analytical Quality Assurance

- Training & Compliance

- Qualification & Validation Section

QUALITY MANAGEMENT SYSTEM

At VINSBIO, quality is more than a mere action; it’s ingrained as a habit. For nearly three decades, our unwavering dedication to quality has been the cornerstone of our mission to give life its fullest expression. Across all facets and sites, our team is dedicated to crafting and delivering products that adhere to the most rigorous quality benchmarks, in alignment with cGMP regulations governing every operational aspect.

Our quality policy, “commitment to care for life,” reflects our profound conviction that quality transcends mere adherence to specifications; it embodies a fundamental ethos for every individual and entity associated with VINSBIO’s offerings.

QUALITY ASSURANCE

The Quality Assurance team owns our QMS. This team ensures quality is built every operation carried out at VINSBIO manufacturing facilities through

- Quality Management System & Documentation

- In-process Quality Assurance (IPQA)

- Analytical Quality Assurance

- Training & Compliance

- Qualification & Validation Section

QUALITY CONTROL

The Quality Control system is seamlessly integrated into every stage of the manufacturing process. Our Laboratory is equipped with sophisticated instruments andapproved technical employees that ensure a highly efficient quality control process. The QC lab includes:

- Instrumentation laboratory

- Packaging material testing laboratory

- Biological testing laboratory

- Microbiological testing laboratory

- Documentation section

- Stability chambers, Incubators and Control sample storage area

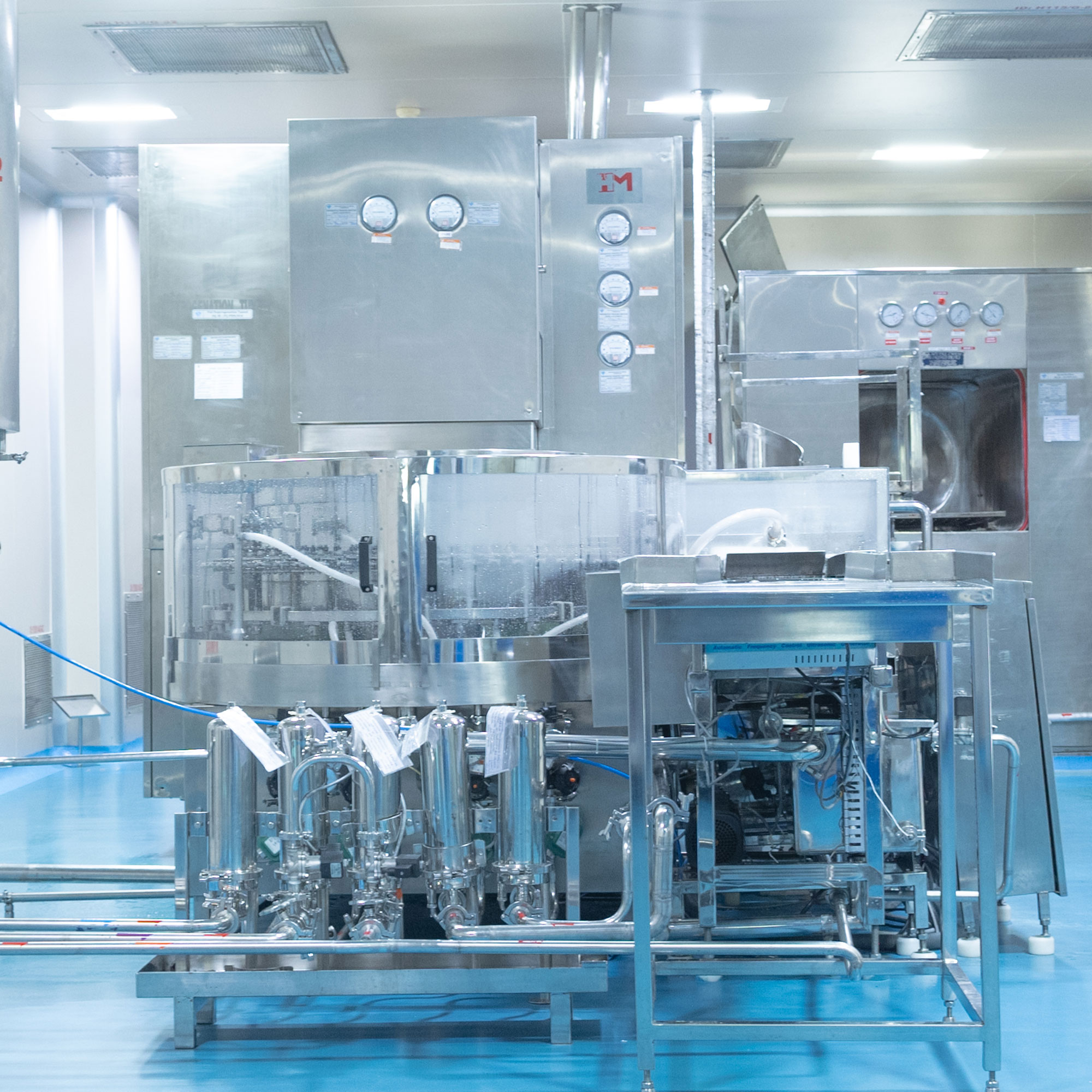

Facility

Our Thimmapur facility started in 2007 as a single manufacturing unit involved in the manufacture of Equine biological products.

Today the Thimmapur facility is segregated in two plants:Plant - I and Plant – II

MANUFACTURING FACILITY | TYPES OF PRODUCTS |

Plant – I | |

Ground Floor | Equine Facility |

First Floor | Pathology Lab |

Plant – II | |

Ground Floor | Production Facility |

First Floor | Walk in Stability Chambers |

Second Floor | Quality & Research Labs |

Third Floor | Cafeteria & Utilities |

Fourth Floor | Quality Assurance |

Fifth Floor | Corporate Office |

The State-of-the-art manufacturing unit incorporates the following features:

- Unidirectional material flow.

- Automated equipment to minimize manual interventions.

- Dedicated manufacturing lines based on product category.

- Automated equipment to minimize manual interventions.

- Validated manufacturing process and in-process controls to ensure consistent product quality.

- 100 % visual inspection of filled and sealed units to ensure zero defect in market.

- Country specific packaging material artwork control.

- ERP based inventory management.

- Dedicated, temperature-controlled storage areas for storage of raw material, intermediate products and finished products.

- State-of-the-art utility support:

- Purified water for injection generation and distribution plant.

- HVAC systems dedicated to every manufacturing line.

- Boiler and Pure steam generator.

- Compressed air generation plant.

- Effluent treatment plant.

- Un-interrupted electrical power supply.

Production capacity: 10 Million units / Annum

- Unit – II: 10 Million units / Annum.

Accreditations

We are proud to share that our manufacturing plant has earned multiple accreditations from esteemed international regulatory agencies, in addition to meeting all necessary approvals granted by Indian regulatory authorities. These accreditations speak to our commitment to quality, safety, and efficacy in our products and manufacturing processes.

Our plant has undergone rigorous inspections and assessments by international regulatory agencies to ensure that our operations comply with the highest standards of safety and quality. As a result, we have been awarded accreditations that are recognized worldwide, reflecting our dedication to meeting and exceeding the expectations of our clients and consumers. We remain committed to upholding these high standards as we continue to grow and innovate in the pharmaceutical industry.

Contact Info

- Survey No.117, Thimmapur (Village) Kothur (Mandal) Ranga Reddy (Dist) - 509325 Telangana, India.

- +91 8548256400

- info@vinsbio.in